Rotary Dryer Manufacturer in Ahmedabad, Gujarat, India

Principle of Rotary Dryer in India

A Rotary Dryer operates on the principle of moisture removal through heat transfer and mass transfer, utilizing a rotating drum to facilitate uniform drying.

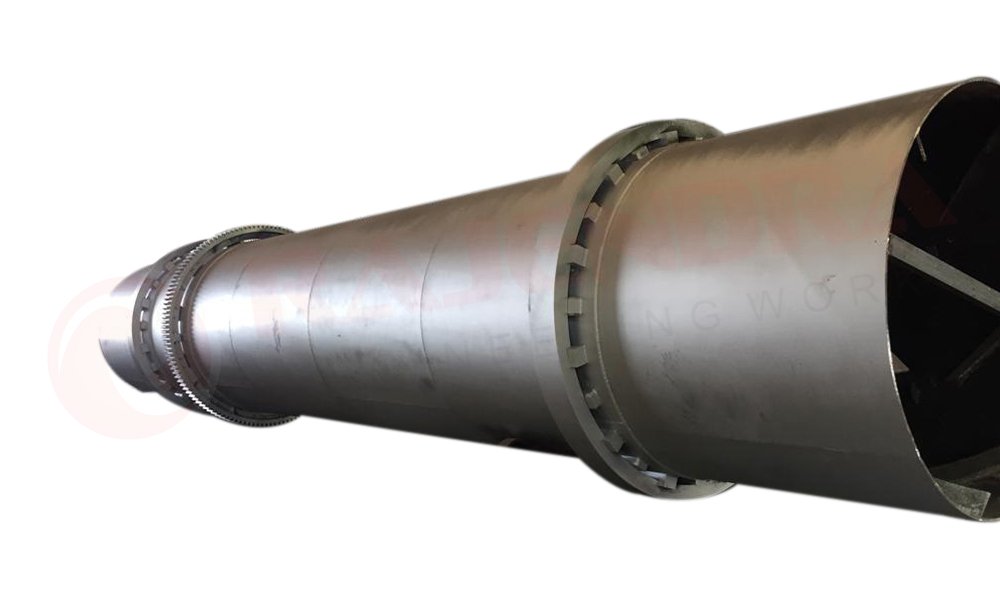

The manufacturing facility of the enterprise is situated within the industrial sector of the state, and is a specialist manufacturer of Rotary Dryers. The objective of Rotary Dryer is to provide innovative solutions for resolving the difficulty of moisture extraction, and is an expert manufacturer of Rotary Drum Dryers. The quality of the Dryer is also ensured through the use of high-quality steel and precision alignment of rollers, which provide a smooth and continuous rotation of the Dryer body. Based in Ahmedabad, REW is able to carry out stringent quality control on all welds and on every component with mechanical properties such as the Girth Gears and drive systems, thereby ensuring reliable performance of all Ahmedabad-manufactured Rotary Dryers for use in local and national manufacturing industries.

The Rotary Dryer Manufacturer in India

REW is an Indian-based manufacturer that has been recognized as one of the leading rotary dryer manufacturers. They manufacture Industrial Rotary Dryers for many Industries such as Agriculture, Heavy Mining, and more. Their engineering staff builds Industrial Rotary Dryers designed around India’s diverse climatic conditions so that the production of Industrial Rotary Dryers remains unaffected by any humidity or extreme temperatures.

Rajendra Engineering Works provides broad-based EPC support to customers across the Country to assist them in optimizing their drying processes while lowering their fuel consumption. This Partnership is built on over 30 years of Engineering Expertise in India combined with World-Class Drying Technology.

Key Features & Applications of Rotary Dryer in India

High Thermal Efficiency

- The rotary dryer efficiently transfers heat to the material through conduction, convection, or radiation.

- Advanced designs incorporate heat recovery systems to reduce energy consumption.

- Insulated rotary drums minimize heat loss and improve efficiency.

Continuous and Uniform Drying

- Rotating drum motion ensures the material is evenly exposed to heat.

- Internal lifting flights (or lifters) toss and mix the material for uniform drying.

- Prevents clumping, over-drying, and inconsistencies in moisture content.

Versatile Application

- Mining & Minerals (e.g., drying sand, limestone, phosphate, etc.)

- Agriculture (e.g., drying grains, corn, soybeans, and sugar beets, Grapes)

- Biomass & Wood Processing (e.g., drying sawdust, wood chips, and pellet

- Food Industry (e.g., drying coffee beans, starch, and spices)

- Chemical & Pharmaceutical (e.g., drying catalysts, fertilizers, and powders)

- Sludge & Waste Management (e.g., drying sewage sludge and industry Waste)

Large Processing Capacity

- Suitable for handling large volumes of bulk materials.

- Can operate continuously for high production rates.

- available in small-scale (lab use) and large-scale (industrial) models.