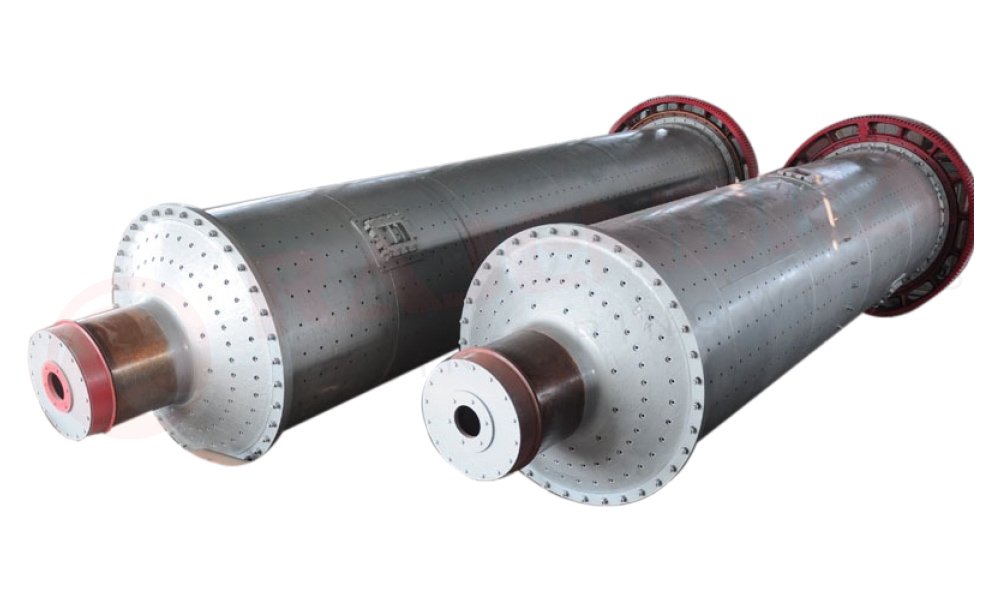

Ball Mill Manufacturer in Ahmedabad, Gujarat, India

Principle of Ball Mill

A Ball Mill operates on the principle of impact and attrition to grind materials into fine powder. Ball Mill is widely used in mining, cement, chemicals, pharmaceuticals, and ceramics for size reduction and material mixing.

India's Leading Ball Mill Manufacturer

REW is a leading Ball Mills Manufacturer in India, supplying heavy-duty grinding equipment that is the backbone of the cement and mineral processing industries. Ball Mills are built for the large amounts of raw materials Indian Industry consumes, with custom-designed liners and grinding media per mill to deliver the specific micron range needed. High-capacity grinding mills manufactured from REW’s central manufacturing facility are available to customers across the entire Indian subcontinent. Every Ball Mill manufactured is built for long life, very low maintenance, and maximum production throughput, providing a solid reputation for being a trusted partner in the growth of India’s infrastructure.

Key Features & Applications of Ball Mill in India

High Grinding Efficiency

- Uses grinding media (balls) to break down materials efficiently.

- Can grind a variety of hard, brittle, or fibrous materials.

- Suitable for dry or wet grinding processes.

Versatile Applications

- Used in mining (ore processing), cement, chemical, pharmaceutical, paint, and ceramics industries.

- Can handle materials like limestone, ores, coal, pigments, and more.

- Available in batch-type or continuous operation models.

Adjustable Particle Size

- Fineness of the product can be controlled by

- Varying ball size and material (steel, ceramic, rubber).

- Adjusting speed, milling time, and feed rate.

- Using different liners and grinding media.

Multiple Grinding Media Options

- Uses steel balls, ceramic balls, or pebbles depending on material and application.

- Choice of media size and hardness affensinding efficiency.

- Rubber or steel liners improve performance and reduces wear.